Titanium projects

Nalgene water bottles are known for being very strong so adding a titanium shell is extremely unnecessary but a hell of a project challenge, so here are the results. Made from grade 1 0.063” sheet that was rolled, plasma cut and anodized.

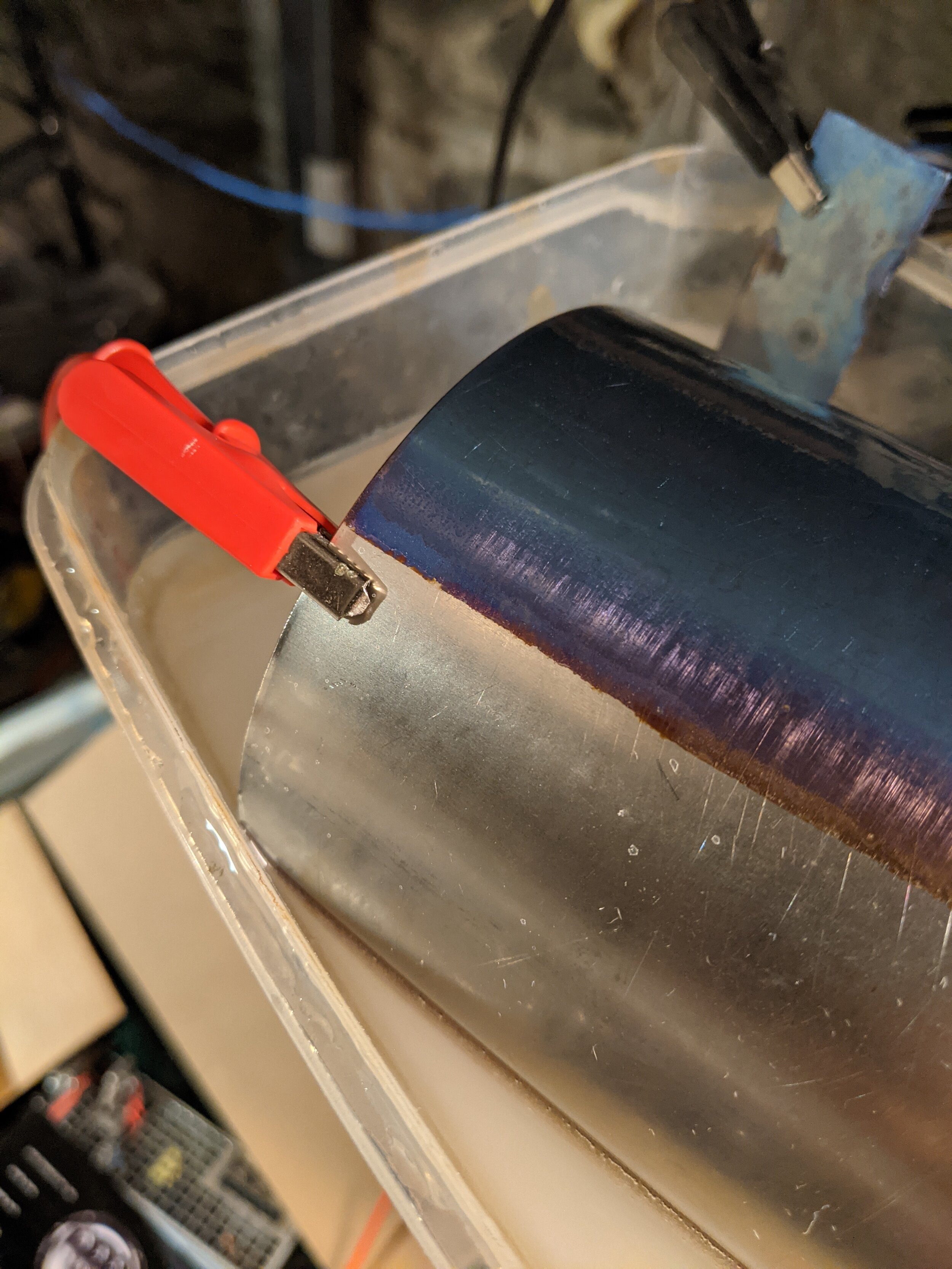

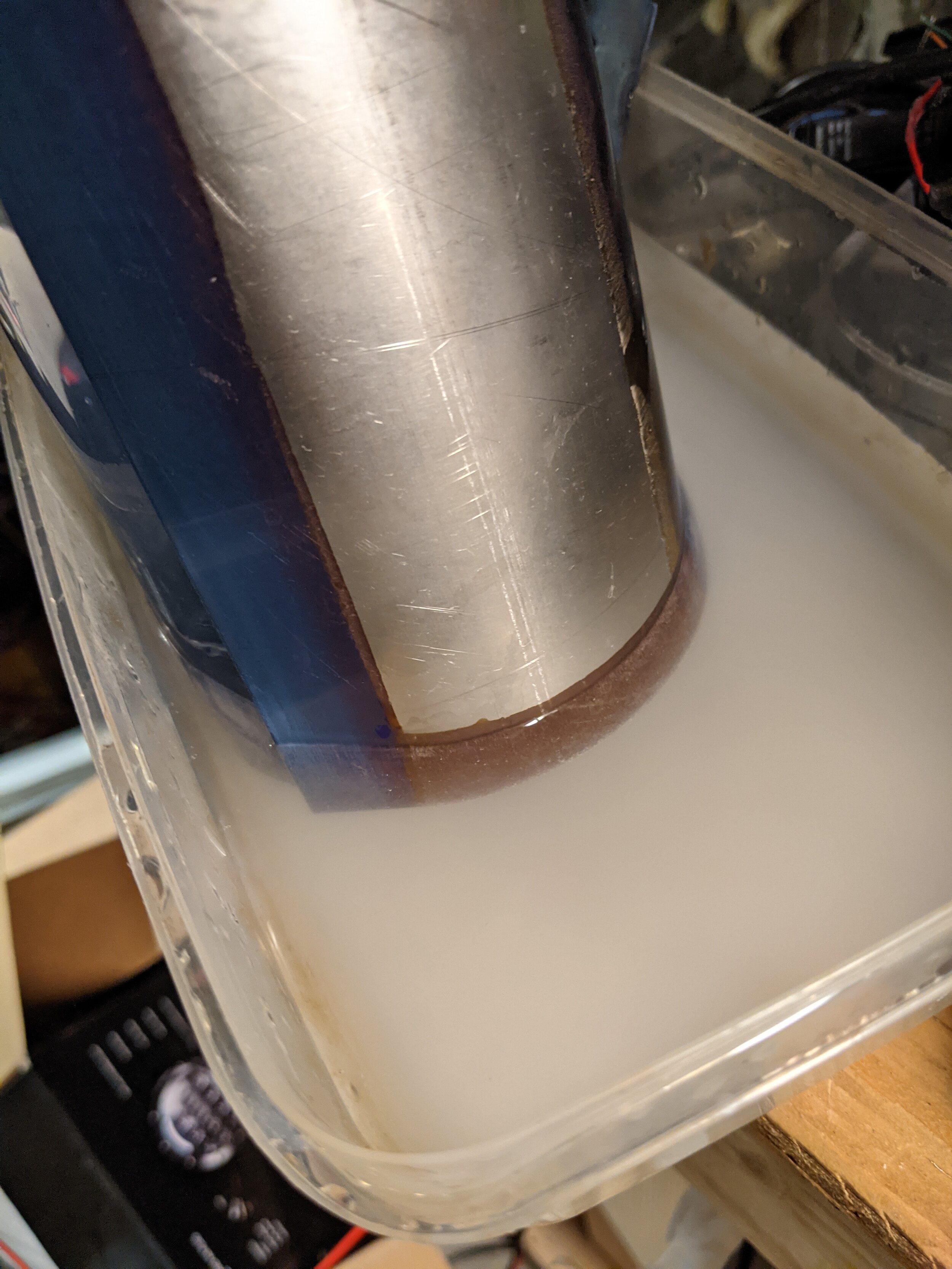

The anodizing was done using about 28v DC in a bath of sink water and baking soda. While a larger bath might have worked I would have likely maxed out the supply at 5A, so half dipping it worked in a smaller bath. Color wasn’t perfect but that wasn’t a requirement for the project.

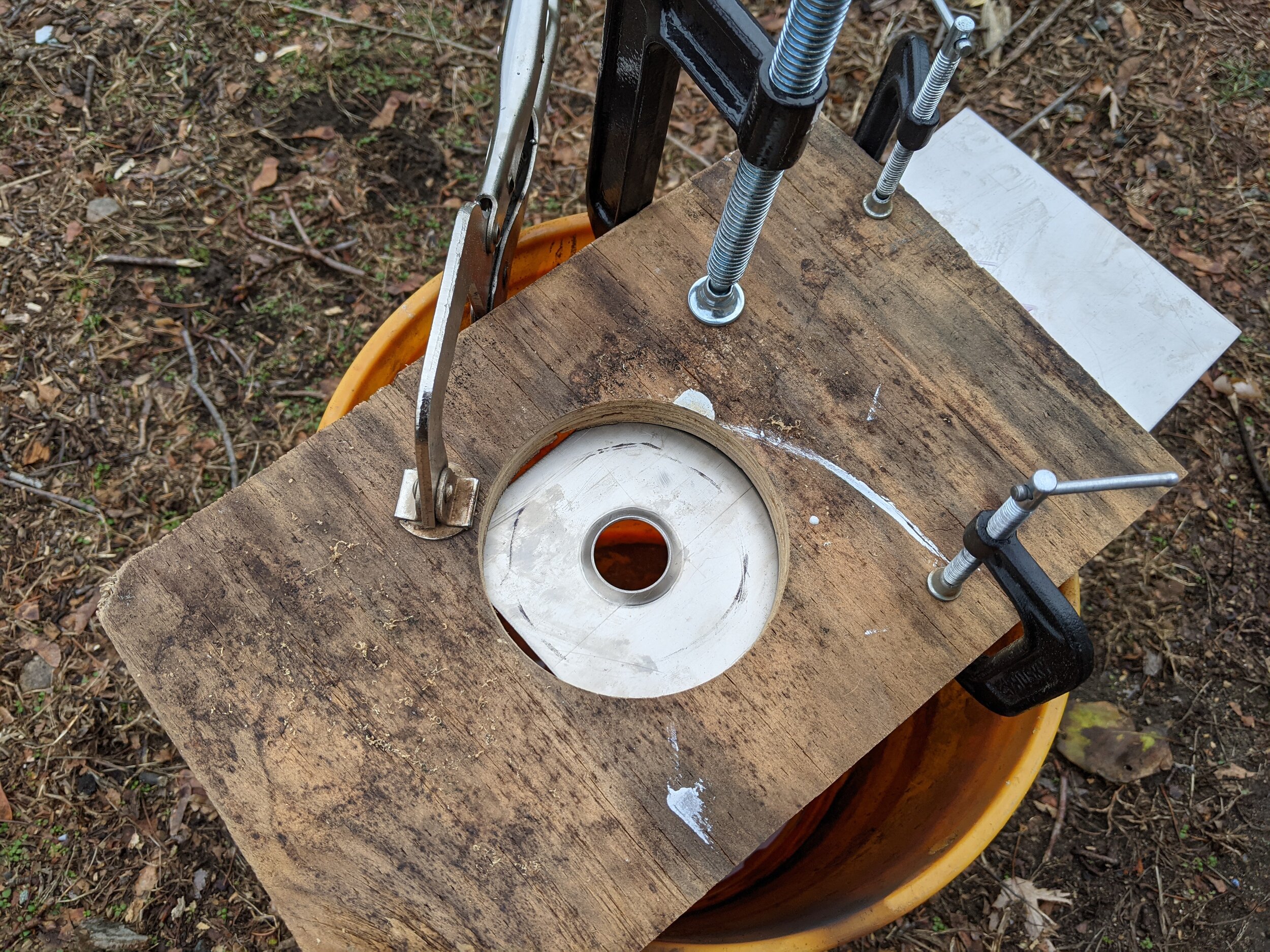

The rolling of the sheet was the original motivator for the project, I had a piece that I experimented with in the roller and realized it was a lot more fun to work with than Gr5. If I had a larger hole saw I wouldn’t have had to plasma cut it for the base of the holder. The inner circle was easy enough to cut with a 1” hole saw and olive oil for lubricant on the cutting and dimpling.

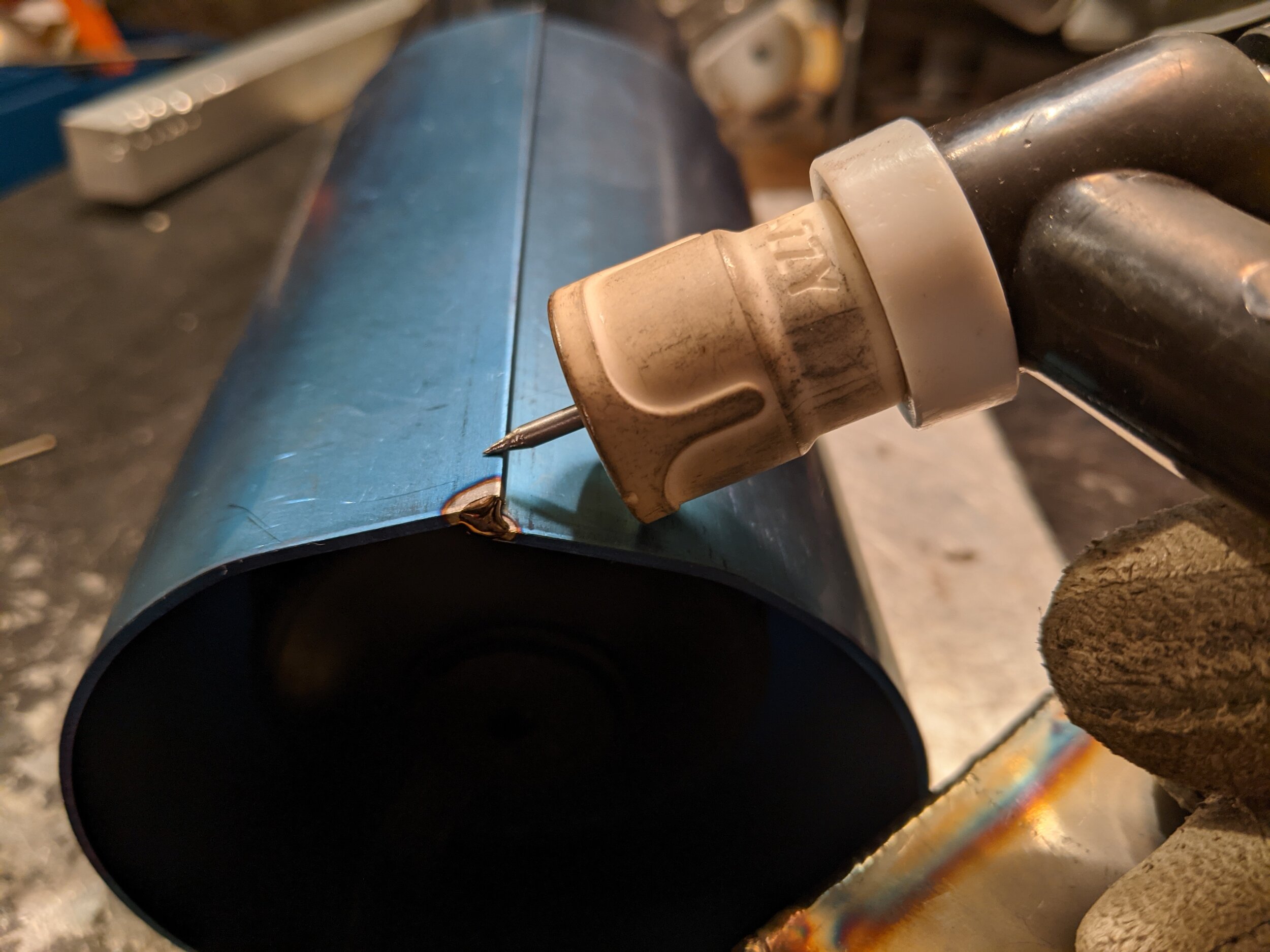

The real challenge of this project was keeping the the back side of everything purged during the welding. For the longer weld this was easier but the small pieces that held the end cap and that were folded down on the top were really tricky to hold and purge. Welding in a bubble would have been ideal but not worth the cost of argon for silly project.

It was a good learning experience for all of the practice it provided, however, it’s now much heavier and likely to scratch things. So maybe worth it?